Main Content

Taconova centralised heat interface units: updated range for flexible planning, straightforward installation and hygienic DHW

Connection-ready, safe and from one source. Centralised heat interface units with higher vertical range of manufacture and improved software:

-

Heating and drinking water circulation pumps are key components in centralised heat interface units.

-

Pump key component now from our company:

-

Primary pumps:

TacoFlow3 GenS (TacoTherm Fresh Mega3) and TacoFlow3 MAX (TacoTherm Fresh Peta2 X) -

Circulation pumps for drinking water systems:

TacoFlow2 PURE C (TacoTherm Fresh Mega3 (X) and TacoTherm Fresh Peta2)

-

-

Optimised proprietary controller software

-

Higher draw-off rate with Peta2 X

-

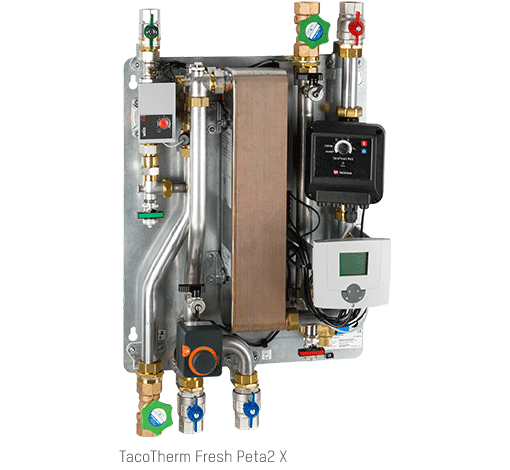

New product design for Peta2 (X)

TacoTherm Fresh Peta2 (X)

Application

- Centralised DHW heating and requirements for reducing the amount of DHW stored (stagnation volume)

- Buildings in which DHW is not used continuously (sports facilities, etc.)

- Reduction in flow temperatures for DHW heating (e.g. in conjunction with heat pumps)

- Combination with buffer cylinders and various heat sources (solar/pellets)

Product benefits

- Straightforward planning due to large output spectrum and cascades

- Broad application area in conjunction with low temperature heating systems

- Simple and cost effective installation due to complete pre-assembly and cascade sets

- Reliable operation due to high vertical range of manufacture and use of own components as well as BMS option

- Safe operation of DHW heating through reduction of stagnation volume

Technical information

- Nominal performance (at primary = flow 70 °C / secondary = 60 °C; ∆p ≥ 100 mbar)

- TacoTherm Fresh Peta2: 64 l/min

- TacoTherm Fresh Peta2 X: 98.5 l/min

- Centralised heat interface unit controlled electronically

- Up to 5 cascade modules possible

- Interface to the building management system

- SVGW certificate 1808-6782

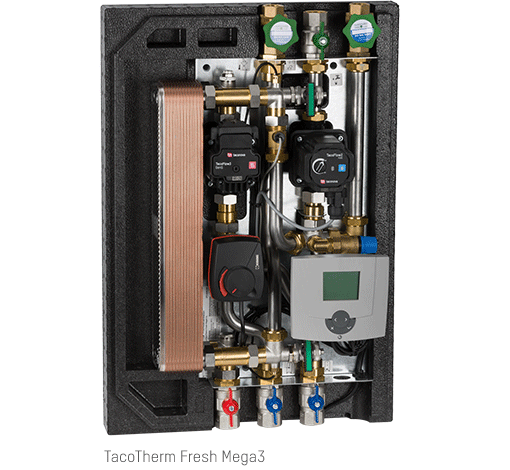

TacoTherm Fresh Mega3 (X)

Application

- Centralised DHW heating and requirements for reducing the amount of DHW stored (stagnation volume)

- Buildings in which DHW is not used continuously (sports facilities, etc.)

- Reduction in flow temperatures for DHW heating (e.g. in conjunction with heat pumps)

- Combination with buffer cylinders and various heat sources (solar/pellets)

Product benefits

- Straightforward planning due to large output spectrum and cascades

- Broad application area in conjunction with low temperature heating systems

- Simple and cost effective installation due to complete pre-assembly and cascade sets

- Reliable operation due to high vertical range of manufacture and use of own components as well as BMS option

- Safe operation of DHW heating through reduction of stagnation volume

Technical information

- Nominal performance (at primary = flow 70 °C / secondary = 60 °C; ∆p ≥ 100 mbar)

- TacoTherm Fresh Mega3: 22.5 l/min

- TacoTherm Fresh Mega3 X: 34 l/min

- Centralised heat interface unit controlled electronically

- Up to 5 cascade modules possible

- Interface to the building management system

- SVGW certificate 1808-6783

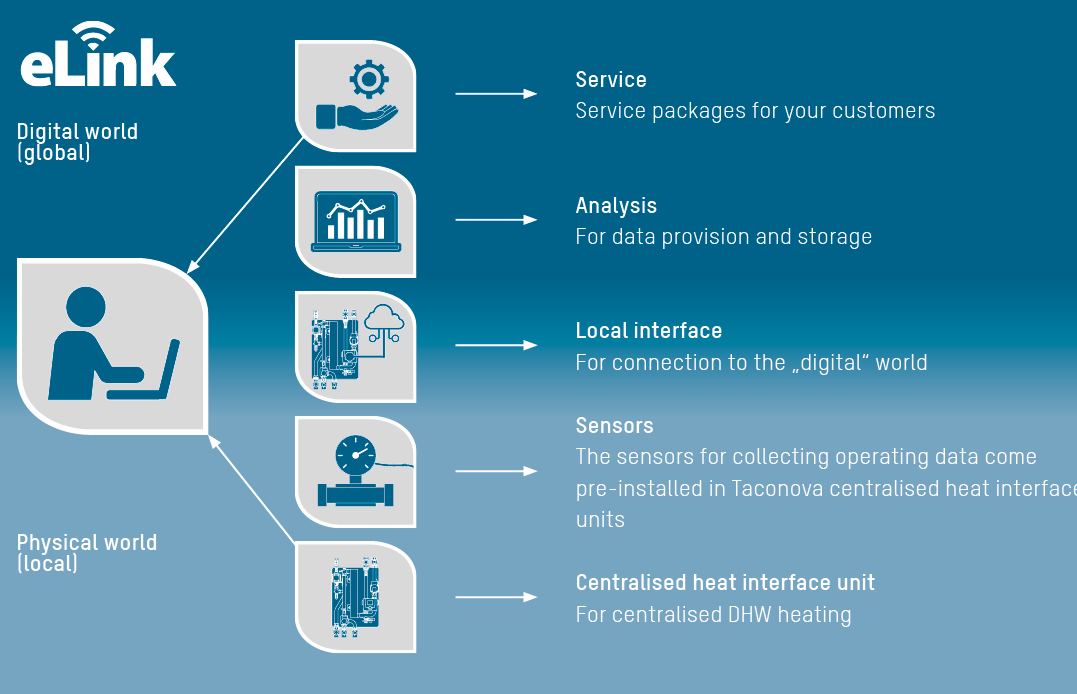

eLink connectivity for centralised heat interface units

Are you interested in remote maintenance of our centralised heat interface units?

Contact our Customer Service at info@cluttertaconova.com for advice specific to your situation.