Main Content

Here is an overview of the ten most frequently asked questions about hydronic balancing.

TacoSetter (Inline, Bypass and Hyline)

Use in weather-compensated or room temperature controlled heating and cooling systems

1. Where should I read off the flow rate – at the top or bottom edge of the float?

You should read off the flow rate at the bottom edge of the float.

2. Can a TacoSetter take flow in either direction?

No, the flow must only be in the direction of the arrow.

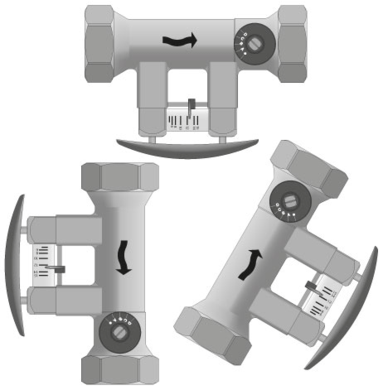

3. Can it be installed in any position?

Yes, essentially any installation position is possible, including sideways or even upside down. There is just one exception, though: on the TacoSetter Bypass, the bypass handle must not be at the top, otherwise air can build up in the inspection window.

4. What do the letters (A, B, C...) on the TacoSetters mean?

The highest letter represents the most open setting of the wheel, which allows the maximum flow rate through the valve. Each additional letter then reduces the flow rate progressively.

5. Are TacoSetters fitted with shut-off devices?

Yes, all TacoSetters are fitted with shut-off devices. Residual leakage is still possible, however.

6. Does closing or disconnecting the bypass have any effect on the main flow rate?

No, it does not affect it.

7. At what percentage of glycol can TacoSetters be operated?

They can be operated at up to 50 % glycol.

8. Why are glycol correction curves available only up to DN25?

For larger dimensions, no correction factor is required, since any variations will fall within measuring tolerances.

9. What is the red slider on the Bypass for?

The red slider is what is known as a memory slider. It can be adjusted by hand so that the setpoint is highlighted and easy to see.

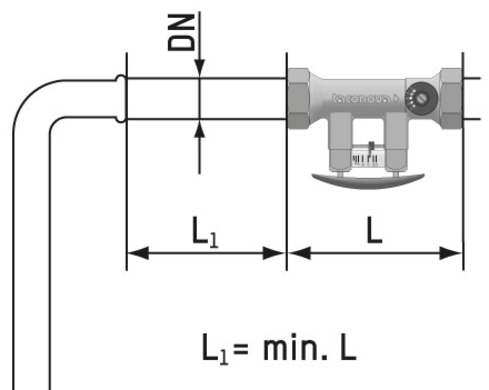

10. Does a TacoSetter require a straight inlet run? If so, how long does it have to be?

Yes, it does need a straight inlet run, equal to the length of the TacoSetter itself.

Know-how

You can find further information about hydronic balancing here.